Making a durable and elegant packaging box for products is not possible without choosing the right packaging material. If you are a business owner, finding the most suitable material to make custom boxes for your products is essential for you.

It is challenging to analyse the properties of different product box materials and pick one for your products. Let’s make it convenient for you with a detailed guide on common materials used for custom boxes.

We will be exploring the characteristics and benefits of some remarkable custom box material types to help you find the best one for your boxes. Let’s dive in:

Cardboard

Cardboard is one of the most common materials for making robust and elegant boxes. The best thing about this material is its customisability. You can easily personalise cardboard boxes in shapes, sizes, and designs according to your preferences.

This exclusive material also supports various printing techniques like digital, offset, flexography, etc. You can add your brand elements to custom cardboard boxes without any hassle.

Based on the coated sides, cardboard material can be categorised into the following types:

-

C1S Cardboard

C1S cardboard is an excellent material for making custom boxes for lightweight items. On this cardboard, only a single side is coated and the other side is plain. On C1S cardboard boxes, you can imprint the images and textures of your liking only on one side.

-

C2S Cardboard

C2S cardboard is famous for its high-end feel, as both sides are coated. C2S cardboard boxes can surprise your customers, as you can imprint them from outside and inside as well. These boxes can be used to enhance the elegance of your retail products ultimately boosting your sales.

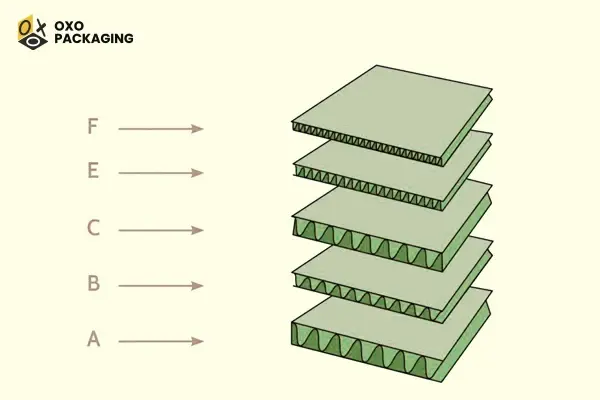

Corrugated Stock

Corrugated stock is a multilayered and durable material used to make protective packaging boxes. This wood-based material is also cost-efficient and offers packaging solutions that do not burden your budget.

Corrugated boxes are famous for their shock-absorbing qualities making them excellent for shipping purposes. They come with single, double and triple-fluted layers. Depending upon their flutes, they can be categorised as:

-

A-Fluted Corrugated Stock

A-fluted corrugated stock is the thickest one among all types of corrugated stocks. The height of their flutes is about 5mm making them suitable for making large storage boxes.

-

B-Fluted Corrugated Stock

With a thickness of about 3mm, B-fluted corrugated stock makes excellent retail and mailer boxes for your products.

-

C-Fluted Corrugated Stock

C-fluted corrugated stock is also considerably (about 4mm) thick. You can use them as shipping boxes and pack fragile items like glasses, crockeries, and decoration pieces in them.

-

E-Fluted Corrugated Stock

E-fluted is a material famous for its medium thickness. It is 1.5 mm thick and excellent for making robust boxes.

-

F-Fluted Corrugated Stock

One of the most sleek corrugated sheets comes with F-fluted corrugated stock that is around 1mm thick.

-

N-Fluted Corrugated Stock

The thinnest and most fine-looking stock is N-fluted corrugated stock with a thickness of around 0.5mm.

Rigidstock

Rigidstcok is one of the sturdiest and most premium custom packaging materials that you can use to make exceptional custom boxes. Custom rigid boxes are mostly used to pack luxurious products like jewellery, watches, smart gadgets and other high-end products.

Spending upon the wall of thickness, here are 3 commonest categories of Rigidstock:

-

1mm Rigid Boxes

The thinnest rigidstock is 1mm thick. As the manufacturing material is significantly sturdy, it is difficult to fold the wall of even 1mm thick rigid packaging boxes. This material is mostly used to make small-sized yet elegant boxes for different types of products.

-

2mm Rigid Boxes

2mm rigid boxes fall in the category of medium packaging boxes that are significantly sturdy. High-end magnetic closure packages and remarkable shoulder boxes are mostly made of this material. You can easily customise them according to your preferences.

-

3mm Rigid Boxes

The most durable and sturdiest packaging boxes are made of 3mm Rigidstock. If you are looking for luxurious packaging with the utmost durability, you can benefit from this 3mm packaging material. You can conveniently make large boxes from this material and pack your products in them without hassle.

Kraft

According to research conducted by PR Newswire:

“71% of buyers intentionally opt for items due to the eco-friendly factor of their product packaging.”

Kraft is one of the most eco-friendly materials that you can use to make your product packaging boxes. Its biodegradability and recyclability make Kraft boxes the first choice for eco-conscious buyers. It also attracts people due to its rustic charm and persuades them to buy your products.

Here are three types of kraft paper depending upon its colours:

-

Natural Kraft Paper

Naturally, Kraft paper comes in brown shaded. It resembles the colour of wood giving them a natural appeal. Many cosmetics, food, and other brands use natural kraft boxes to showcase that they are close to nature, and their products are made of natural ingredients.

-

White Kraft Paper

When bleached and processed, the kraft can be given any colour. You can comfortably alter your kraft packaging boxes in white colour to depict the simplicity of your product and brand. The white colour is significantly reflective, so it is excellent to draw the attention of buyers.

-

Black Kraft Paper

Another popular colour for kraft paper boxes is black. The dark colour persuades prospects who like premium packages. Black Kraft boxes can be easily customised to make them excellent for packing gift products.

Chipboard

Chipboard is one of the most affordable materials for making packaging boxes used for the storage of goods. This material is made of recycled cardboard or paperboard and is less strong than other types of packages. They are used to pack products that are not required to be packed in sturdy boxes.

Bux Board

Buxboard is made of recycled cardboard and is significantly tough. Unlike chipboard, you can use this material to make protective packaging boxes for your products. However, Bux board boxes are also rugged and rough in appearance, so they are not the best choice to pack premium and high-end products.

Materials for Custom Boxes Inserts

Custom boxes come with various inserts that improve their functionality. These inserts also provide extra protection to the products packed in the product boxes. Here are some common materials used to make custom boxes’ inserts:

- Polyurethane (PU) foams

- Polyvinyl chloride (PVC) inserts

- Polyethylene (PE) foams

- Velvet, polyester and silk cloths

- Polyethylene terephthalate (PET) inserts

Custom Boxes Lamination & Coating Materials

Finishing and coating custom boxes is highly important to enhance their visual appeal. The following are some common lamination and coating materials used to enhance the elegance of packaging boxes:

- Matte enamel

- Gold foil lamination

- Silver foil lamination

- Polyethylene terephthalate (PET) gloss lamination

- Holographic film made of polyester (PET), oriented polypropylene (OPP) and nylon

Conclusion

Finding the right materials used for personalised product packaging boxes is highly important for business owners. They need the material that resonates with their brand requirements and present their products in the best possible way. Here, we have discussed in detail about all the packaging material options you can choose from.

If you are still confused, feel free to reach out. OXO Packaging is your packaging partner to find the most suitable packaging material for your products and make custom boxes according to your preferences.